The Role of Pressure Sensors in Coffee Machines

Coffee machines have become an indispensable appliance for many, delivering high-quality coffee quickly and efficiently. One key aspect that determines the quality of coffee in modern machines is the control of pressure. Pressure sensors play a vital role in regulating the pressure during coffee extraction, ensuring consistency and precision with every cup. In this article, we will explore how pressure sensors are applied in coffee machines, the benefits they offer, and their importance in both home and commercial coffee brewing systems.

Introduction to Pressure in Coffee Machines

Pressure is a critical factor in the coffee brewing process, particularly for espresso machines. Espresso requires water to be forced through finely-ground coffee at high pressure to extract its rich flavors, oils, and aroma. The standard pressure for brewing espresso is typically around 9 bars, but this can vary depending on the machine and user preferences.

If the pressure is too low, the coffee may be under-extracted, leading to weak and watery flavors. Conversely, too much pressure can result in over-extraction, creating a bitter and unpleasant taste. This is where pressure sensors come into play, allowing coffee machines to precisely monitor and control the brewing pressure to ensure optimal extraction.

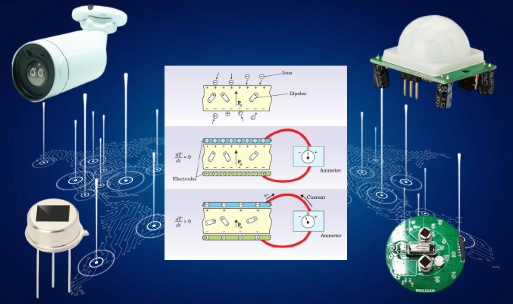

How Pressure Sensors Work in Coffee Machines

Pressure sensors in coffee machines monitor the pressure within the brewing system, providing real-time data to ensure consistent extraction. These sensors detect changes in pressure and send signals to the control unit, which can then adjust the pump or valve settings accordingly.

There are different types of pressure sensors used in coffee machines, each with specific characteristics suited to the brewing process. The most common include ceramic pressure sensors

Glass Micro-Fusing Pressure Transmitter

The Glass Micro-Fusing Pressure Transmitter is a cutting-edge technology used in coffee machines to precisely control and monitor pressure during various stages of coffee preparation, especially in high-end espresso machines. Here’s a detailed look at its application in coffee machines:

1. Pressure Regulation for Espresso Extraction

Espresso brewing relies on the accurate control of pressure, typically around 9 bars, to force hot water through finely-ground coffee. This pressure ensures the extraction of rich flavors, oils, and crema, creating the perfect shot of espresso.

The Glass Micro-Fusing Pressure Transmitter provides precise and stable pressure measurements, allowing the machine to maintain the optimal brewing pressure throughout the process. Its durability and high accuracy ensure that even with continuous use, the pressure stays consistent, which is critical for maintaining the quality of the coffee.

2. Durability in High-Temperature Environments

During espresso brewing and steam generation, coffee machines are exposed to high temperatures. The glass micro-fusing technology ensures that the transmitter can withstand these temperatures without performance degradation. Unlike traditional adhesive-bonded sensors, the glass micro-fused bond is highly resistant to temperature fluctuations, making it ideal for coffee machines that cycle between brewing and steaming.

3. Steam Pressure Control for Frothing Milk

In addition to brewing coffee, many machines also need to generate steam for frothing milk. The steam pressure needs to be carefully controlled to create the right texture and consistency for milk-based drinks like lattes and cappuccinos.

The Glass Micro-Fusing Pressure Transmitter ensures that the steam pressure remains stable and can be adjusted as needed for different types of drinks. The sensor’s ability to handle both high pressures and high temperatures makes it a perfect fit for this function in coffee machines.

4. Safety and Overpressure Protection

Overpressure situations in coffee machines can lead to mechanical failures or even dangerous accidents. To prevent this, pressure transmitters play a key role in monitoring and managing pressure limits.

Glass Micro-Fusing Pressure Transmitters are highly reliable and ensure that any overpressure conditions are detected quickly, triggering safety mechanisms to prevent equipment damage or user injury.

5. Improved Coffee Machine Performance and Longevity

The robust construction of the Glass Micro-Fusing Pressure Transmitter means that it offers enhanced durability and longevity compared to other pressure sensors. This is particularly important in commercial coffee machines, which are subjected to continuous use and harsh operating conditions.

The long-term stability of these sensors minimizes maintenance needs and ensures that coffee machines perform reliably over time.

6. Compact and Space-Saving Design

The micro-fusing technology allows for a more compact sensor design, which is beneficial in the space-constrained environment of modern coffee machines. This compactness allows manufacturers to integrate advanced pressure control features into smaller coffee machines without sacrificing performance.

7. Consistent Coffee Quality

With the precision provided by Glass Micro-Fusing Pressure Transmitters, coffee machines can consistently brew high-quality coffee. Whether for home use or commercial environments, maintaining the correct pressure during each brew cycle ensures that the coffee tastes the same with each use, which is critical for customer satisfaction.

The WPCK89 digital output pressure transmitter is a new generation of intelligent digital products, characterized by high precision, high reliability, convenient use and installation. The product has a wide voltage range, low power consumption, and multi-level protection design, with strong anti-interference ability. The standard IIC bus has a maximum speed of 400K, a collection rate of 50 times/second, a power consumption of less than 2mA during operation, and a standby current of 1uA. The standard IIC communication protocol makes this transmitter particularly suitable for computer control systems.

Get Price WhatsappApplications of Pressure Sensors in Coffee Machines

Pressure sensors are integral to several key functions within coffee machines, particularly in espresso machines where precise control of pressure is essential. Here are some of the main applications of pressure sensors in coffee machines:

1. Pressure Regulation in Espresso Machines

In espresso machines, the brewing process requires water to be forced through the coffee grounds at a high pressure, typically around 9 bars. Pressure sensors monitor the pressure throughout the brewing process, ensuring that it remains within the ideal range for optimal extraction.

If the pressure falls outside of the desired range, the sensor sends a signal to the machine’s control system, which can adjust the water pump or valve settings accordingly. This real-time adjustment ensures that each shot of espresso is brewed with the perfect balance of flavor and aroma, providing a consistent and high-quality coffee experience.

2. Steam Pressure Control for Frothing Milk

Many coffee machines, particularly those designed for making cappuccinos and lattes, have a steam wand used for frothing milk. The pressure sensor plays a critical role in controlling the pressure of the steam. To create the ideal foam texture, the steam must be delivered at a consistent pressure. Too much pressure can overheat the milk, while too little pressure may not create enough foam.

Pressure sensors in the steam system monitor and maintain the right steam pressure, ensuring that the milk is frothed to perfection with the desired texture and consistency.

3. Preventing Overpressure

Overpressure in coffee machines can cause several issues, including damage to the machine, inconsistent coffee extraction, and safety risks. Pressure sensors are essential for preventing overpressure situations. When the sensor detects that the pressure is too high, the system can automatically reduce the pressure by adjusting valves or shutting down the pump.

This not only protects the internal components of the machine but also ensures that the coffee brewing process remains consistent and safe.

4. Automatic Cleaning Cycles

Many modern coffee machines feature automatic cleaning cycles to maintain hygiene and ensure the longevity of the machine. Pressure sensors play a role in these cycles by monitoring the pressure of water flowing through the system during cleaning. Maintaining the right pressure ensures that the internal components, such as the brewing chamber and steam wand, are thoroughly cleaned without causing damage to the machine.

In addition, pressure sensors can detect blockages in the system that might occur during the cleaning process. If a blockage is detected, the machine can alert the user or automatically take corrective action to resolve the issue.

Benefits of Pressure Sensors in Coffee Machines

The integration of pressure sensors in coffee machines offers several benefits, which contribute to both the quality of the coffee and the performance of the machine.

1. Consistent Coffee Quality

One of the main advantages of using pressure sensors in coffee machines is the ability to maintain consistent coffee quality. By accurately controlling the pressure during extraction, the machine can ensure that each shot of espresso is brewed with the same level of flavor, aroma, and crema. This consistency is particularly important in commercial settings, where customers expect the same quality of coffee with every cup.

2. Improved Machine Performance

Pressure sensors help optimize the performance of coffee machines by ensuring that all processes are carried out at the correct pressure levels. Whether it’s brewing espresso or frothing milk, maintaining the right pressure ensures that the machine operates efficiently and effectively. This leads to improved overall performance, reducing the likelihood of issues such as over-extraction, under-extraction, or equipment failure.

3. Enhanced Safety

Safety is a critical concern in coffee machines, particularly those that operate under high pressure. Overpressure can cause damage to the machine or even pose safety risks to users. Pressure sensors provide real-time monitoring of the system, ensuring that pressure remains within safe limits. If an issue is detected, the system can take immediate corrective action to prevent accidents.

4. Reduced Maintenance Costs

Pressure sensors can help identify potential issues before they become major problems. By detecting pressure fluctuations or anomalies early, the machine can alert the user to potential issues such as blockages, leaks, or component wear. This allows for timely maintenance, reducing the risk of more costly repairs or machine downtime.

The Future of Pressure Sensors in Coffee Machines

As coffee technology continues to evolve, pressure sensors will play an increasingly important role in improving coffee machine performance and user experience. Several trends are emerging that highlight the future potential of pressure sensor technology in coffee machines:

1. Smart Coffee Machines

Smart coffee machines are becoming more common, allowing users to control and monitor their machines remotely using mobile apps or voice commands. Pressure sensors are integral to these systems, providing real-time data that can be accessed by users to ensure optimal brewing conditions. With smart coffee machines, users can customize pressure settings, monitor extraction in real-time, and receive alerts if there is an issue with pressure levels.

2. Enhanced Precision for Coffee Connoisseurs

As the demand for specialty coffee continues to grow, there is an increasing focus on precision brewing. Coffee connoisseurs are seeking machines that allow for greater control over variables such as pressure, temperature, and extraction time. Pressure sensors will be crucial in delivering this level of precision, enabling users to fine-tune their brewing process for the perfect cup of coffee.

3. Integration with AI and Machine Learning

Future coffee machines may incorporate artificial intelligence (AI) and machine learning algorithms to optimize brewing based on user preferences and environmental factors. Pressure sensors will provide valuable data to these systems, allowing the machine to learn and adjust its pressure settings for optimal performance over time.

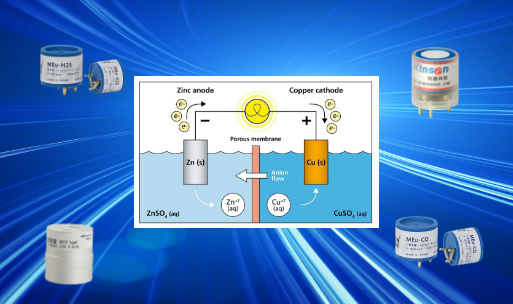

Winsen Pressure Sensors Solution

https://www.winsen-sensor.com/selection-guide/winsen-pressure-sensors-solutions.htmlConclusion

Pressure sensors are a critical component of modern coffee machines, playing a key role in regulating pressure during the brewing process. Whether it’s maintaining the right pressure for espresso extraction, controlling steam pressure for frothing milk, or preventing overpressure situations, these sensors ensure that coffee machines operate efficiently and deliver consistent results.

As coffee technology continues to advance, pressure sensors will remain an essential feature in both home and commercial coffee machines. Their ability to enhance coffee quality, improve machine performance, and ensure safety makes them indispensable in the quest for the perfect cup of coffee.