Photoconductivity Sensors: A Complete Guide to Principles, Materials, Applications, and Innovations

Photoconductivity sensors, also known as photoresistors or light-dependent resistors (LDRs), are a type of light sensor that changes their electrical conductivity in response to variations in light intensity. These sensors operate on the principle of photoconductivity—where a material’s ability to conduct electricity increases as it absorbs light energy. Photoconductivity sensors are widely used across industries, including consumer electronics, industrial automation, environmental monitoring, safety systems, and healthcare.

This article explores the science behind photoconductivity, the key materials used in photoconductivity sensors, their working mechanism, types, advantages, limitations, and real-world applications. It also delves into technological innovations and the future potential of these sensors in modern smart systems.

What is Photoconductivity?

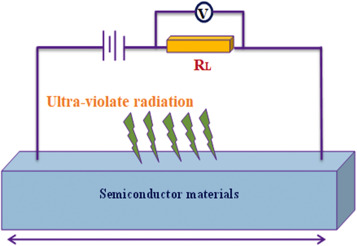

Photoconductivity is the property of certain materials to increase their electrical conductivity when exposed to light. When photons strike a photoconductive material, they excite electrons from the valence band to the conduction band, generating electron-hole pairs. These charge carriers allow current to flow more easily through the material, decreasing its electrical resistance.

The amount of conductivity gained depends on the intensity and wavelength of the incident light. Once the light source is removed, the electrons return to their original state, and the material’s resistance increases again.

Working Principle of Photoconductivity Sensors

Photoconductivity sensors are typically built from semiconducting materials. When no light is present, the sensor maintains a high resistance. When light hits the sensor, it decreases the resistance as more free electrons and holes are created.

Key Steps in Operation:

-

Absorption of Light: The sensor is exposed to light of a particular wavelength.

-

Electron Excitation: Photons with sufficient energy excite electrons from the valence band to the conduction band.

-

Generation of Charge Carriers: Electron-hole pairs are formed, which increases the material’s conductivity.

-

Change in Resistance: The electrical resistance of the sensor decreases, which can be measured as a voltage drop or change in current.

-

Signal Processing: The change in resistance is used as an indicator of light intensity and can be fed to controllers or electronic systems.

This simple but effective process enables photoconductivity sensors to act as reliable detectors in diverse applications.

Types of Photoconductivity Sensors

Photoconductivity sensors can be broadly classified into two categories based on the type of material used:

1. Intrinsic Photoconductors

These are made from pure semiconducting materials like silicon or germanium. The photoconductive effect in intrinsic materials occurs when electrons jump across the natural bandgap without the influence of dopants.

2. Extrinsic Photoconductors

These include semiconductors that have been doped with impurities to create energy levels within the bandgap. Extrinsic photoconductors are more sensitive to longer wavelengths, such as infrared, and are commonly used in more advanced light-detecting applications.

Common Materials Used in Photoconductivity Sensors

Photoconductivity sensors utilize a variety of materials based on their spectral sensitivity and performance characteristics. Below are some commonly used materials:

1. Cadmium Sulfide (CdS)

-

Sensitive to visible light (400–700 nm)

-

Cost-effective

-

Common in light meters, solar lighting, and photo switches

2. Lead Sulfide (PbS)

-

Sensitive to infrared radiation (1–3 µm)

-

Used in flame detectors, gas sensors, and military applications

3. Germanium (Ge)

-

Suitable for infrared detection

-

Low cost, high-performance in near-IR applications

4. Amorphous Selenium (a-Se)

-

Excellent for X-ray and photocopying technologies

-

Exhibits stable photoconductive properties under high-energy radiation

5. Gallium Arsenide (GaAs)

-

Used in high-speed optical systems

-

Suitable for near-IR applications

Electrical Characteristics

When characterizing a photoconductivity sensor, several key parameters are considered:

-

Dark Resistance: The resistance of the sensor in the absence of light, typically high.

-

Photocurrent: The current produced when the sensor is illuminated.

-

Sensitivity: The rate of change in resistance per unit light intensity.

-

Response Time: The time taken to respond to changes in light intensity.

-

Spectral Response: The range of wavelengths to which the sensor responds effectively.

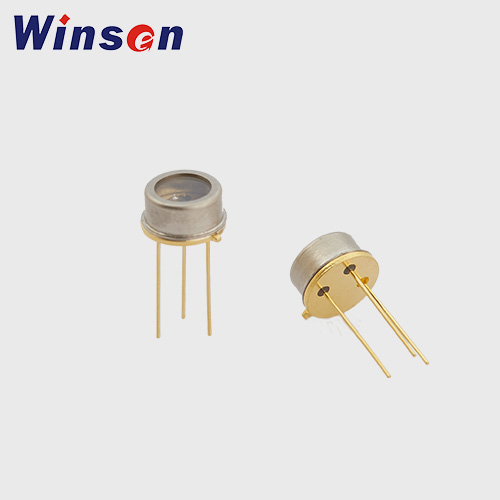

Winsen Photoconductivity Sensor

Applications of Photoconductivity Sensors

Photoconductivity sensors are embedded in countless devices and systems due to their versatility and reliability. Below are some of their major applications:

1. Automatic Lighting Systems

Photoconductivity sensors detect ambient light levels and automatically turn lights on or off. They're widely used in streetlights, solar lamps, and building automation systems.

2. Camera Light Meters

Modern cameras use photoresistors to measure light intensity and adjust exposure accordingly.

3. Safety and Security Systems

These sensors can detect light interruptions and are used in burglar alarms and automatic door openers.

4. Consumer Electronics

Photoconductivity sensors adjust screen brightness on mobile phones, laptops, and televisions based on surrounding light conditions.

5. Infrared and Flame Detection

Special materials like PbS or InSb allow these sensors to be used in industrial furnaces, gas leak detection, and fire safety systems.

6. Medical Imaging and Diagnostics

Used in X-ray detection, mammography, and digital radiography where high-sensitivity photoconductive materials like amorphous selenium are vital.

7. Industrial Process Monitoring

Monitor light levels, product presence, or conveyor belt movement in automated manufacturing systems.

8. Environmental Monitoring

Instruments use photoconductivity sensors to detect changes in light caused by pollutants, cloud coverage, or other environmental factors.

Advantages of Photoconductivity Sensors

-

Simple Design: Easy to integrate into circuits with minimal components.

-

Low Cost: Economical compared to photodiodes and phototransistors.

-

Passive Operation: Does not require external power for operation.

-

Wide Spectral Range: Materials can be selected for sensitivity from UV to IR.

-

Durability: Long operational lifespan and low maintenance.

Disadvantages

-

Slow Response Time: Not suitable for high-speed optical applications.

-

Non-linear Output: May require calibration for precision applications.

-

Temperature Dependency: Resistance may vary with temperature.

-

Toxic Materials: Some materials like CdS and PbS are toxic and require careful disposal.

Photoconductivity vs. Photodiodes

| Feature | Photoconductivity Sensor | Photodiode |

|---|---|---|

| Response Time | Slow | Fast |

| Output Type | Resistance Change | Current Generation |

| Sensitivity | Moderate | High |

| Cost | Low | Moderate to High |

| Applications | Basic light detection | High-speed, precision tasks |

Emerging Trends and Innovations

As the demand for smarter, more responsive, and energy-efficient systems grows, innovations in photoconductivity sensors are on the rise:

1. Nanostructured Materials

Nanomaterials like quantum dots and nanowires offer better sensitivity, reduced response time, and broader spectral detection.

2. Flexible and Wearable Sensors

Research is enabling the integration of photoconductivity sensors into textiles and wearables for health monitoring and ambient sensing.

3. Integrated Optoelectronics

Combining photoconductivity sensors with wireless modules, microcontrollers, and cloud platforms for IoT-based smart applications.

4. Environmentally Friendly Materials

Development of lead-free and cadmium-free photoconductors to reduce environmental impact.

How to Choose the Right Photoconductivity Sensor

When selecting a photoconductivity sensor for a specific application, consider the following:

-

Light Spectrum Sensitivity

-

Response Time Requirements

-

Size and Integration Needs

-

Environmental Conditions (e.g., temperature, humidity)

-

Budget and Cost Constraints

-

Toxicity and Material Safety

Conclusion

Photoconductivity sensors remain one of the most versatile and widely used types of light sensors across various industries. Their ability to translate light intensity into measurable electrical signals makes them invaluable in everything from streetlights and smartphones to medical imaging and security systems.

As technology evolves, these sensors are becoming more efficient, miniaturized, and environmentally conscious. With the integration of nanotechnology and smart electronics, the future of photoconductivity sensors promises enhanced performance and broader application in the era of smart systems and sustainable innovation.