Particulate Matter (PM) Sensors Of Two Different Principles

The particulate matter sensors, with other names of particles sensors, PM2.5 PM10 sensors, dust sensors on the market, are divided to two different types working based on laser and infrared principles. Both types are used to detect particles in the air and monitor indoor air quality and alarm air pollution. What is the difference between them? Let’s make comparisons from below aspect

Structure and Principle

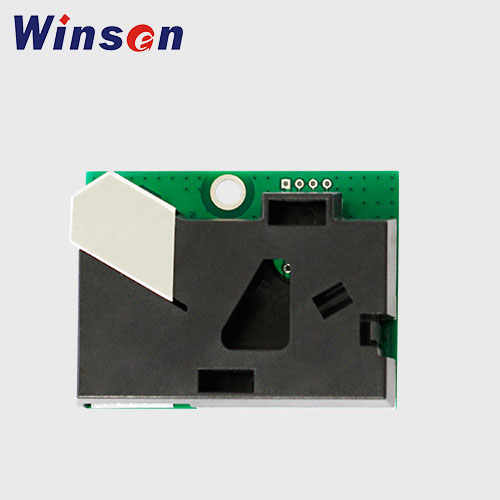

Infrared Particles Sensor

The PM sensor based on the infrared principle is relatively simple in structure. Its has infrared LED light as the light source. According to the principle of light scattering, the light emitted by the LED meets the particles and generates reflection. The photosensitive element detects the light intensity of the reflected light, and judges the particles concentration according to the intensity of the pulse signal by processing and classification algorithms. When there is no particles detected, the output of the photosensitive detector is a low pulse; on the contrary, when particles is detected, the output is a high pulse.

Laser Particles Sensor

Different from the infrared PM sensor, the laser particle sensor has a fan, which can provides a stable air flow, and quickly obtain the PM concentration in the environment.

Because the laser PM sensor uses laser LED as the light source, its structure and circuit are more sophisticated than the infrared sensor. When fine particles or dust in the air are blowed into the laser beam inside the sensor by a constant flow fan, the laser light will scatter. We place a photodetector at an appropriate position so that it only receives scattered light, and then generates an electrical signal through the photoelectric effect; after being amplified by the circuit, the fine particle concentration can be obtained.

Measurement Accuracy

The infrared light has a long wavelength (about 700 to 900nm), and measurement accuracy of infrared PM sensor on particles with an aerodynamic diameter smaller than 1um is insufficient. Because the signal of infrared LED light scattering is weaker than laser light, it only has a relatively obvious response to large particles with diameter more than 1um. Only heating resistor is used to drive the sampling airflow, and the number of samples is small. The measurement accuracy is around ±30%.

The laser PM sensor can detect dust particles as small as 0.3um. Because it comes with a higher-performance MCU, uses a constant-speed fan to increase the air intake and collect higher-density data. The overall measurement accuracy can reach ±10%. Therefore, the laser dust sensor has obvious advantages compared with the infrared dust sensor in measurement accuracy, sensitivity, accuracy and consistency.

Applications

According to customers’ different requirements, Winsen has developed dust sensors with different fans, inlet/outlet, structure and size, etc.The sensors are widely used in dust detectors, purifiers, fresh air systems, smart homes, air conditioners and other fields.