Powering the Future: Exploring Electrochemical Energy Storage Stations

What is Electrochemical energy storage station?

Electrochemical energy storage stations are advanced facilities designed to store and release electrical energy on a larger scale. These stations serve as centralized hubs for multiple electrochemical energy storage systems, enabling efficient energy management and grid integration.

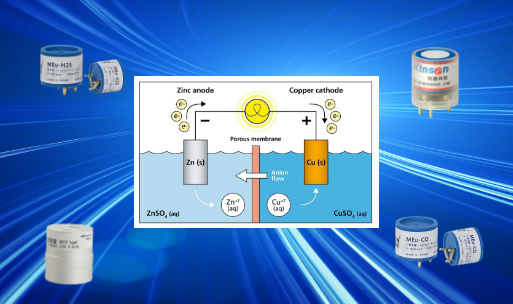

At the core of an electrochemical energy storage station are the electrochemical cells or batteries. These batteries, often lithium-ion or other chemistries, are connected in series or parallel to create battery banks capable of storing a significant amount of electrical energy. The station also includes various supporting components such as power conversion systems, cooling systems, and control systems to ensure optimal performance and safety.

The primary purpose of an electrochemical energy storage station is to address the challenges associated with intermittent energy sources, such as renewable energy. During periods of high energy production or low demand, excess electricity can be stored in the batteries within the station. This stored energy can then be released during peak demand periods or when renewable energy sources are not actively generating power. By storing and releasing energy as needed, these stations help balance the supply and demand of electricity, stabilize the grid, and enhance overall grid reliability.

What are the main components of an electrochemical energy storage station?

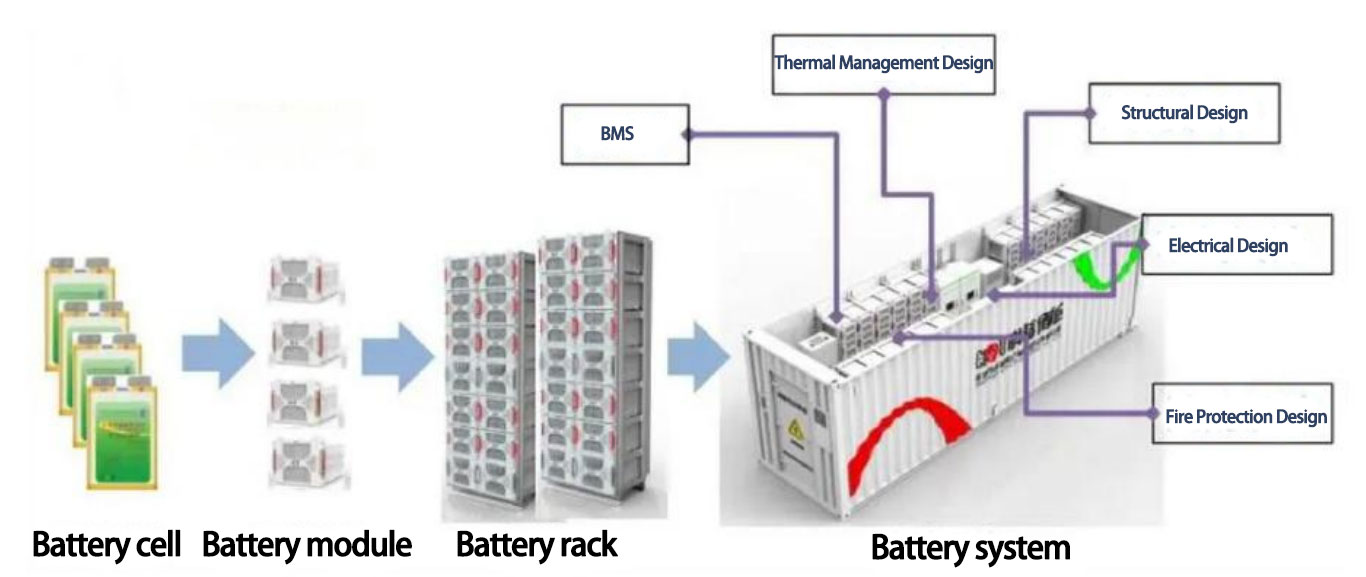

- 1. Battery Management System (BMS): The BMS is a critical component responsible for monitoring and controlling the electrochemical energy storage system. It collects real-time data on parameters like voltage, current, temperature, and state of charge to ensure optimal performance, safety, and longevity of the batteries.

- 2. Thermal Management Design: The thermal management system controls and regulates the temperature within the electrochemical energy storage station. It includes various cooling mechanisms, such as fans, heat sinks, or liquid cooling systems, to maintain the batteries within their optimal temperature range. Proper thermal management helps improve battery performance, efficiency, and lifespan.

- 3. Structural Design: The structural design ensures the stability, integrity, and safety of the electrochemical energy storage station. It involves the selection of appropriate materials, construction techniques, and structural supports to withstand environmental stresses and potential hazards.

- 4. Electrical Design: The electrical design encompasses the wiring, connections, and electrical infrastructure within the energy storage station. It includes the design of power distribution systems, circuitry, and protection mechanisms to ensure efficient and safe electricity flow.

- 5. Fire Protection Design: Fire protection measures are crucial to mitigate fire risks associated with electrochemical energy storage systems. This includes implementing fire suppression systems, using fire-resistant materials, and incorporating fire detection and alarm systems to safeguard the station and surrounding areas.

- 6. Battery Cells: Battery cells are the building blocks of the electrochemical energy storage system. These individual cells contain the electrochemical reactions that store and release electrical energy. The choice of battery chemistry depends on the specific application requirements, such as energy density, power capability, and cycle life.

- 7. Battery Modules: Battery modules consist of multiple interconnected battery cells. They provide a standardized and scalable unit that simplifies the integration and management of the individual cells. Modules typically include additional safety features, such as thermal sensors and fuses, to monitor and protect the battery cells.

- 8. Battery Cabinets or Racks: Battery cabinets or racks house the battery modules and provide mechanical support and protection. These enclosures are designed to ensure proper ventilation, temperature control, and accessibility for maintenance and inspection.

- 9. Battery System Controls: Battery system controls include software and hardware components that monitor and manage the operation of the overall energy storage system. They enable communication, data logging, and remote monitoring capabilities, allowing operators to optimize system performance and respond to any issues promptly.

Pain points of electrochemical energy storage stations

Safety Concerns

Safety is a critical concern when it comes to electrochemical energy storage systems. While modern batteries have improved safety features, there is still a risk of thermal runaway, fire, and explosion, albeit rare. Proper design, monitoring, and maintenance protocols are necessary to ensure the safe operation of energy storage stations. Ongoing research and development efforts are focused on improving battery safety and mitigating potential risks

Related Read:

Safeguarding Energy Storage: Advanced Sensors for Safety Monitoring

Gas Detection in Lithium Battery Thermal Runaway

Gas Detection and Early Warning Solutions for Lithium Battery Energy Storage Systems

Cost

One of the primary pain points of electrochemical energy storage stations is the cost. The initial investment required for deploying large-scale energy storage systems can be significant. While the cost of energy storage technologies, such as lithium-ion batteries, has been decreasing over the years, it still remains a barrier for widespread adoption, especially for grid-scale applications. However, as technology advances and economies of scale improve, it is expected that the cost of electrochemical energy storage systems will continue to decline.

Limited Lifespan

Electrochemical energy storage systems, including batteries, have a limited lifespan. Over time, the performance of batteries can degrade, reducing their energy storage capacity. This degradation is primarily due to chemical reactions and physical changes that occur within the battery cells. Ensuring the longevity and durability of electrochemical energy storage systems is a challenge that requires ongoing research and development efforts.

Environmental Impact

The production and disposal of electrochemical energy storage systems can have environmental implications. The extraction of raw materials, such as lithium and cobalt, for battery production can have negative environmental impacts, including habitat destruction and pollution. Additionally, the proper disposal and recycling of batteries are crucial to minimize their environmental footprint. Developing sustainable and environmentally friendly manufacturing processes and recycling techniques is essential to address this pain point.

Regulatory and Policy Frameworks

The regulatory and policy frameworks surrounding the deployment of electrochemical energy storage stations can be complex and vary across different regions. Streamlining and harmonizing regulations and policies related to energy storage can facilitate its widespread adoption. Clear guidelines on permitting, interconnection, and grid integration can help overcome regulatory barriers and accelerate the deployment of energy storage systems.

How to protect energy storage station safety?

As a sensor manufacturing company, we play a crucial role in enhancing the safety of energy storage stations.

- Temperature Sensors: Incorporate temperature sensors within the energy storage system to monitor the temperature of the batteries and other critical components. These sensors can provide real-time temperature data, allowing the battery management system (BMS) to take appropriate measures to prevent overheating and thermal runaway.

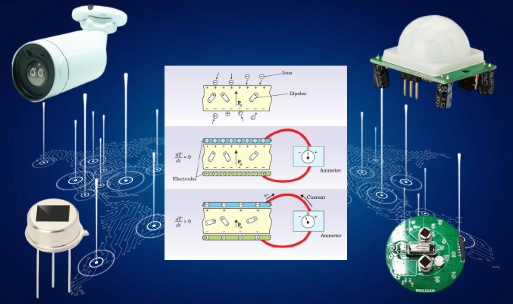

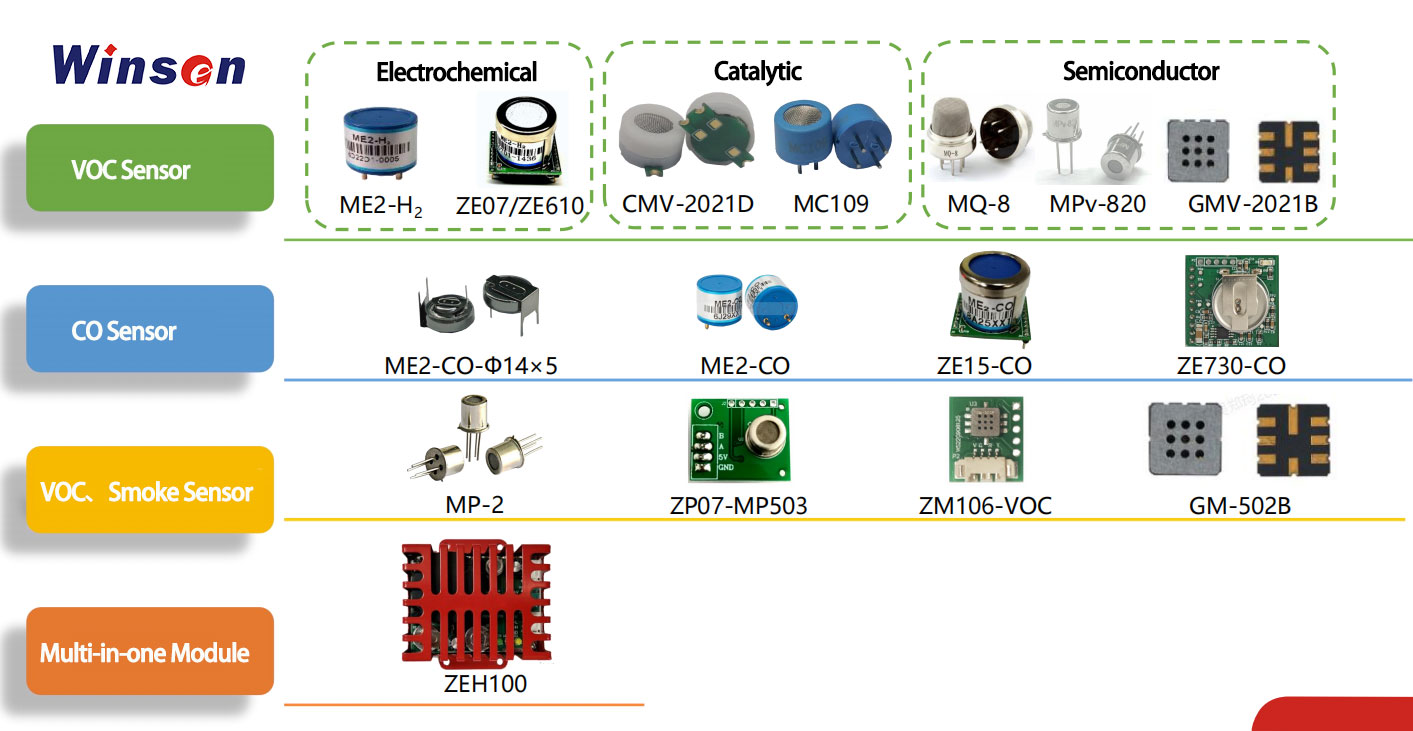

- Gas Sensors: Install gas sensors to detect and monitor potentially hazardous gases, such as hydrogen or sulfur dioxide, which can be released during battery malfunctions. These sensors can trigger alarms or activate safety measures to mitigate the risks associated with gas leaks or build-up.

- Smoke and Fire Sensors: Integrate smoke and fire sensors throughout the energy storage station to detect early signs of smoke or fire. These sensors can provide immediate alerts to initiate fire suppression systems, evacuate personnel, and prevent the spread of fire.

- Current and Voltage Sensors: Utilize current and voltage sensors to monitor the electrical parameters within the energy storage system. These sensors help detect any abnormalities in the current or voltage levels, indicating potential faults or malfunctions. Early detection allows for timely intervention to prevent safety hazards.

- Pressure Sensors: Deploy pressure sensors to monitor the pressure levels within the battery cells or enclosures. Sudden pressure changes can indicate internal faults or gas build-up, which can lead to safety risks. Pressure sensors can trigger alarms or safety protocols to address these issues promptly.

- Humidity and Moisture Sensors: Install humidity and moisture sensors to monitor the moisture levels within the energy storage station. Excessive moisture can lead to corrosion or short circuits, posing safety risks. These sensors can detect moisture accumulation and trigger actions to mitigate the issue.

- Vibration Sensors: Utilize vibration sensors to monitor the vibration levels of critical components within the energy storage system. Unusual vibrations can indicate mechanical stress or structural issues, which may compromise the safety and integrity of the system. Vibration sensors can detect these abnormalities and prompt inspections or maintenance.

- Communication and Data Analysis: Enable communication capabilities in the sensors to transmit data to the central monitoring system or BMS. This facilitates real-time monitoring and analysis of sensor data, allowing for early detection of potential safety risks and proactive measures to be taken.

- Sensor Calibration and Maintenance: Ensure regular calibration and maintenance of the sensors within the energy storage station. This helps maintain their accuracy and reliability, ensuring that they can effectively detect and report safety-related parameters.

Winsen Sensors for Energy Storage Safety Monitoring

Working in conjunction with other safety measures, the sensors play a vital role in early detection, monitoring, and prevention of safety hazards, ensuring the reliable and secure operation of these stations.

Conclusion

In conclusion, electrochemical energy storage stations are cutting-edge facilities that enable efficient energy management and grid integration. By storing excess electricity and releasing it when needed, these stations contribute to a more sustainable, reliable, and resilient energy infrastructure. As technology continues to advance, electrochemical energy storage stations will play an increasingly vital role in our transition to a cleaner and more sustainable energy future.